Particleboard

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

Particleboard is also called chipboard, because it is made from small chips of wood glued together and compressed in a high-temperature press.

Different glues are used to bond the fibres, such as:

- Urea formaldehyde - for 'standard' grade particleboard not exposed to moisture

- Melamine formaldehyde and urea formaldehyde combined - for 'moisture resistant' particleboard used in kitchens, bathrooms and laundries

- Phenol formaldehyde - for high strength sheet flooring.

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

For example, paraffin wax is used to increase the board's resistance to water and to reduce the swelling that occurs if it gets wet.

Fire retardants, insecticides and fungicides are also used to improve the board's durability and performance.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

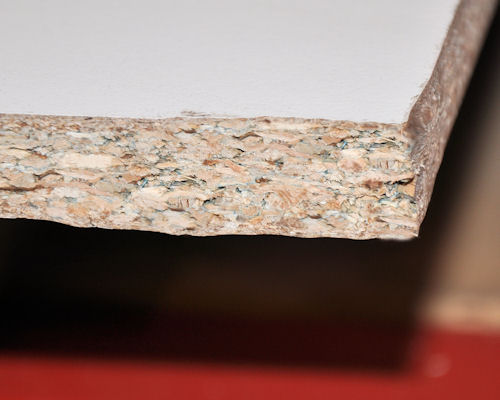

The board is actually built up in layers.

The most common structure is three-layer particleboard, which has fine particles and more adhesive in the two outer layers and a coarse layer in the middle.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

Advantages

Particleboard is easy to re-saw and machine.

Nails and screws have reasonable holding power when used properly, and joints can be glued for extra strength.

It is a very cost-effective substrate for plastic laminates and timber veneers, and it does not swell or shrink, as long as it's kept dry.

Melamine-faced moisture-resistant particleboard is particularly suitable for cabinet carcases and shelves.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

Disadvantages

The biggest weakness of particleboard is its inability to resist moisture.

Once it gets wet and 'blows up', it doesn't shrink back to its original thickness.

Instead, the board loses strength and becomes crumbly where it has swollen.

Although moisture-resistant board performs much better than standard board, it still needs to be protected from direct wetting.

Learning activity

Audio 7 (mp3 |6|KB)Moisture resistant particleboard generally has a green tinge to it, especially on the edge of the board.

If you haven't noticed this before, go out to your workshop storage area or local building supply company and compare the colour of a sheet of standard grade board with a moisture resistant board.

While you're looking closely at the edge, check out the three different layers.

Why do you think it's useful to have a fine texture on the top and bottom faces and a coarser layer in the middle?

Share your answer with your trainer and other learners in your group.