Assignment

Your trainer may ask you to complete this assignment as one of the assessment requirements for this unit. For more information about the assessment process and advice on what to do if you need help with your reading and writing, click on the link below.

Assessment requirements

Assignment for Section 2: Using tools on-site

Task 1

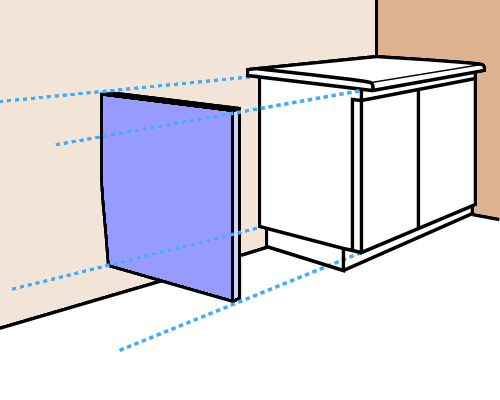

This task deals with two scenarios where a vanity cabinet is being installed in the corner of a bathroom. In both instances the rear wall is out of plumb, but in opposite directions.

You have decided to hide the tapered gap between the cabinet and wall by fitting an end panel (the blue panel shown in the diagram at right).

The end panel will go from the underside of the bench top to the bottom of the cabinet, above the kickboard. It will fit hard against the wall and finish flush with the front of the door. Although the wall is out of plumb, it is flat, so the tapered side of the end panel will form a straight line and won't need to be scribed.

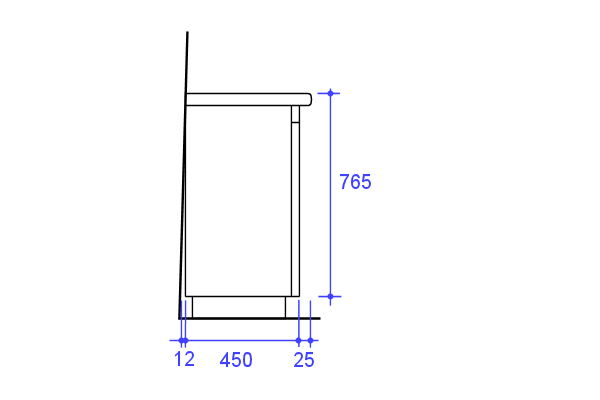

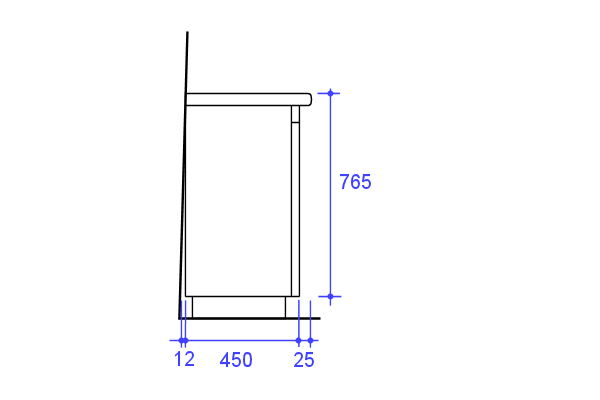

You take the following measurements relating to the cabinet, and produce a quick detail drawing of each scenario (as shown in the diagrams below).

Bench top thickness: 35 mm

Height from top of kickboard to top of bench top: 765 mm

Width of cabinet (including door): 450 mm

Bench top overhang: 25 mm

| Scenario 1 | Scenario 2 |

|

|

Task 2: Power tools

This Task is designed to help you to prepare for your practical assessment event, where you will be asked to demonstrate your ability to re-cut or shape a panel using one or more power tools. The tools you're likely to use will be an electric plane and a jig saw.

Choose either the plane or the jig saw and write up a brief safe operating procedure (SOP), using the template provided.

To see an example of a completed SOP, click on the 'Sample SOP' link below. This example relates to a circular saw, which has many similarities with a plane and jig saw in terms of safety considerations.

You may also consult the manufacturer's instruction booklet or an existing workplace SOP for more information, and include some of that material in your SOP.

Doc (140 KB) Using tools on-site template

Click on the link above to go to the Word document you will need to complete. You should fill in your answers on-screen and then either:

- print out a hard copy to send to your trainer by post

- save the file electronically to submit to your trainer as an email attachment.