Sharpening cutting edges

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

In fact, tools that are designed to be razor sharp - such as knives and chisels - tend to go blunt very quickly while you're using them, especially if you're cutting hard materials.

In the case of utility knives, you can simply replace the blade once the edge goes dull.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

But many people find it easier to send them to a professional sharpening service, or simply replace them with a new set.

Note that plywood and particleboard will dull sharp blades more quickly than solid timber, because the glue in these manufactured boards is harder than the wood fibres.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

Chisels

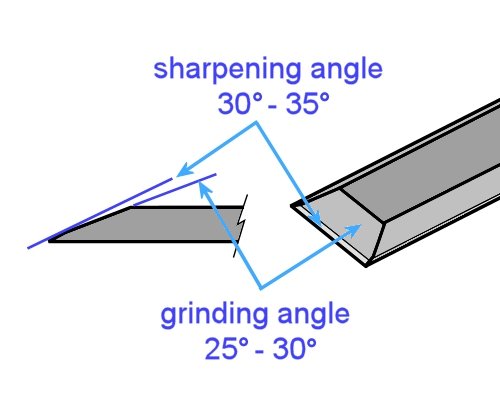

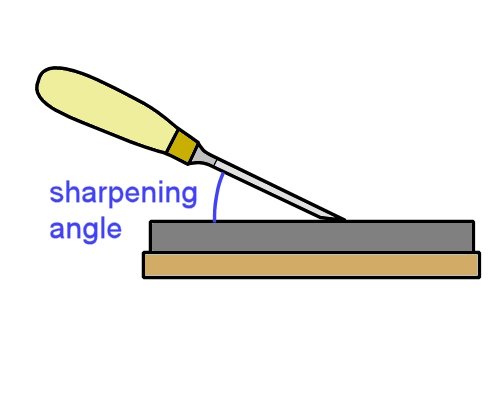

There are two important angles at the sharp end of a chisel - the grinding angle and the sharpening angle.

The grinding angle is formed on a grinding wheel. It should be between 25° to 30° from the face of the chisel blade.

The sharpening angle is between 30° to 35°. This is the angle that gives you a sharp cutting edge, so it's the one you must maintain by 'honing' the chisel regularly on an oilstone.

If you're cutting softwood or doing very delicate work, keep the angle closer to 30°, because that will give you a sharper blade. But for harder materials, an angle closer to 35° is better, because the edge is less brittle, so it's less likely to break away while you're cutting.

Audio for slide 7 (mp3 |6|KB)

Audio for slide 7 (mp3 |6|KB)

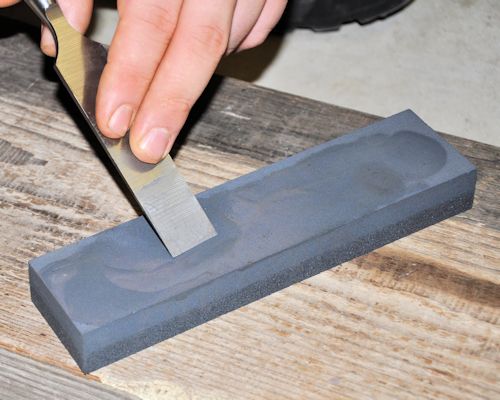

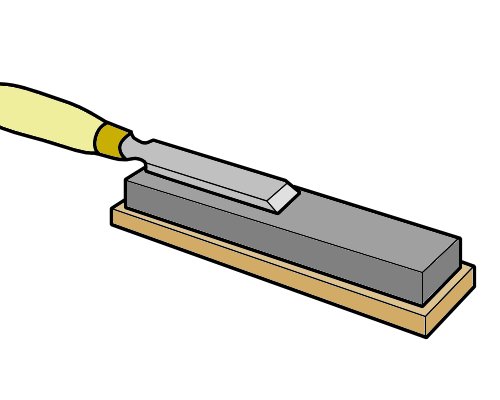

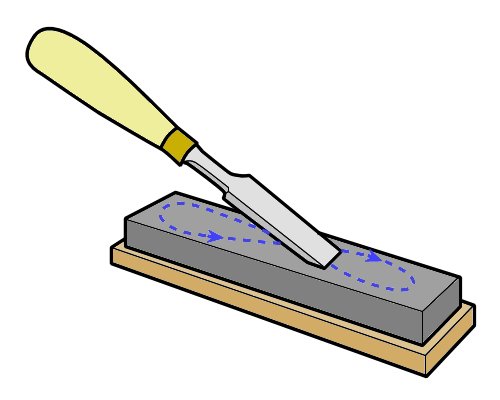

- Turn the chisel over and raise it to the point where the grinding surface is flat against the surface of the stone.

Then lift the chisel up slightly further to find the sharpening angle. - Rub the chisel in a figure-eight pattern on the stone to hone it.

A tiny burr will form on the back of the blade at the edge, called a 'wire edge'.

Audio for slide 9 (mp3 |6|KB)

Audio for slide 9 (mp3 |6|KB)

Grinding

After repeated sharpenings, the angle of the sharpening bevel will start to increase as the end gets progressively shorter.

Eventually, you'll need to regrind the chisel to get back to a full-length 25° flat surface.

When you're grinding the chisel, be very careful to avoid overheating the edge, because this will cause the steel to lose its strength or 'temper'.

Cool the edge frequently by dipping it in water.

The video clips referenced in the learning activity below shows the procedures used to grind and hone a chisel.

Audio for slide 10 (mp3 |6|KB)

Audio for slide 10 (mp3 |6|KB)

Drill bits

Like chisels, drill bits will lose their edge at different rates, depending on what materials you're working with.

Metals, manufactured boards and surface laminates will all take their toll on the cutting edges of a drill bit.

There are various machines and jigs designed for sharpening drill bits. Some of these are quite cheap and available in any hardware store. But many tradespeople like to sharpen their own drill bits by hand, using either a grinding wheel or hand file.

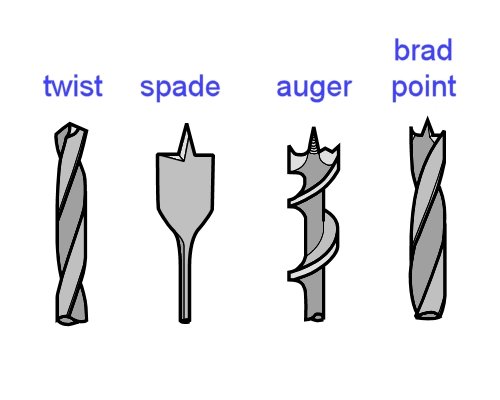

The equipment and technique you use will depend on the type of drill bit you're sharpening.

Audio for slide 11 (mp3 |6|KB)

Audio for slide 11 (mp3 |6|KB)

There may also be times when you use an auger or brad point.

Follow the links in the learning activity below for more information on how to sharpen each of these types of drill bits.

Learning activity

Audio 12 (mp3 |6|KB)Below are some links to web pages and YouTube video clips showing how to sharpen chisels and drill bits. We'll concentrate on the procedures used to hone a chisel on an oilstone and grind a twist drill on a bench grinder. These are the two skills you're most likely to use in your day-to-day work.

Also below are references to pages and clips showing other procedures relating to sharpening chisels and drill bits. These are for your own general interest. You'll find many other video clips on YouTube - just type in phrases like: 'How to sharpen a wood chisel', or 'How to sharpen a drill bit'.

Honing a chisel on an oilstone

Sharpening a chisel and plans iron

Watch the video clip and then answer the following questions:

- What sharpening angle does the demonstrator use for his honing?

- How does he remove the wire edge?

Sharpening a twist drill

Have a look at the photos and read the text beside each photo. Then scroll down to the video clip and watch it. Answer the following question:

- What is wrong with 'sweeping the edge too far back' when you turn the drill bit while grinding it on the grinding wheel? That is, what will it do to the cutting edge?

More information

For a demonstration on how to grind a chisel on a bench grinder, go to:

Grinding and honing a chisel freehand

For details on how to sharpen auger, spade and brad point bits, go to: